Products

Polyurethane Chemicals

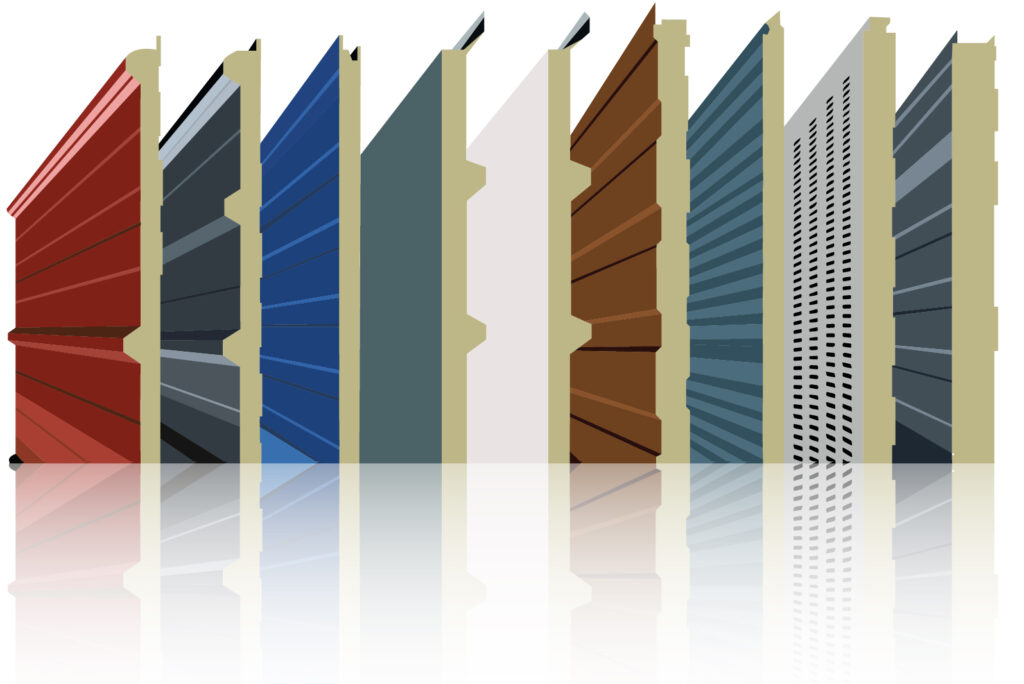

Continiuous Panel Systems

- ISP CP 236 series blended polyols are continuous PUR sandwich panels system designed for 2 Component Machine with n-Pentane as blowing agent. They are widely used in the insulation layer of workshop, prefabricated houses and common building.

- Excellent operationally, flowability, adhesive strength and good demolding are the main features when they react with PMDI (normal functionality) which is the recommended isocyanate for the formulation

- The manufactured foam has a fire behaviour B2 grade according to DIN 4102, good density distribution, high compressive strength and excellent dimensional stability.

- The thickness of the foamed polyurethane core can range from 100 mm to 200 mm depending upon required insulation characteristics.

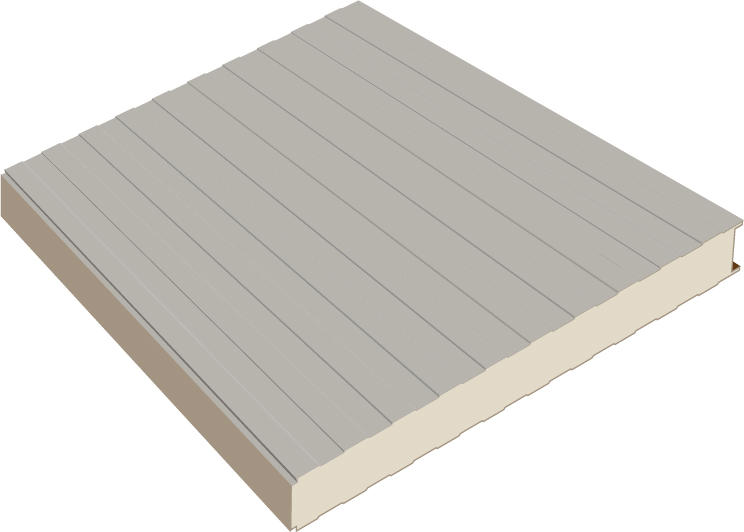

Discontinuous Panel Systems

- ISP DP 28 series blended polyols are discontinuous PUR sandwich panels system designed with n-Pentane as blowing agent. They are widely used to produce panels for different applications,such as cold storage, manufactured housing, climate-controlled rooms, warehouse, etc.

- Excellent operationally, flowability, adhesive strength and good demolding are the main features when they react with PMDI (normal functionality) which is the recommended isocyanate for the formulation..

- The manufactured foam has a fire behaviour B3 grade (O.I.<23%) according to DIN 4102, good density distribution, high compressive strength and excellent dimensional stability.The thickness of the foamed polyurethane core can range from 50mm to 200mm depending upon required insulation characteristics..

Block System

- ISP BF 40-2 series blended polyols are a block rigid foam system designed with n-Pentane and HFC – 365mfc/227ea as blowing agent. They are widely used to produce polyurethane foam boards for different applications, such as cold storage, refrigeration trucks, climate-controlled rooms, warehouse, etc.

- Excellent operationally, flowability, adhesive strength and good demolding are the main features when they react with PMDI (normal functionality) which is the recommended isocyanate for the formulation.

- The manufactured foam has a fire behaviour B3 grade (O.I.<23%) according to DIN 4102, good density distribution, high compressive strength and excellent dimensio- nal stability

- The thickness of the foamed polyurethane core can range from 50mm to 200mm depending upon required insulation characte- ristics.

Refrigerator - Freezer

- ISP APU 28 series blended polyols are designed to be used with cyclopentane blowing agent, and are reddish brown transparent liquid at room temperature.

- Mainly used as the polyurethane insulation layer for refrigerator or freezer manufacturing.

Boilers (Water Heaters)

- ISP PP 36 W series blended polyols are designed which blowing agent is just water and are reddish brown transparent liquid at room temperature

- Mainly used as the polyurethane insulation layer for ice box or water heater manufacturing

Adhesives

- ISP RWA 703 series are adhesive for producing EPS and Mineral Wool adhesion properties to metal surface when they react with PMDI (normal functionality) which is the recommended isocyanate for the formulation.Mainly used as the polyurethane insulation layer for refrigerator or freezer manufacturing.

Decorative-Wood Imitation Systems

- ISP PP 73 series are decorative- wood imitation polyurethane rigid foam systems which blowing agent is HFC – 365mfc/227ea

- Polyurethane foam producing from these systems has a fire behaviour B3 grade according to DIN 4102 .

- They are widely used in decorative construction, the foam has a good dimensional stability when they react with PMDI (normal functionality) which is the recommended isocyanate for the formulation.

Cold Room Systems

Spray Systems

- ISP SP 33 series are spraying polyurethane rigid foam systems which blowing agent is HFC-365mfc/227ea. Polyurethane foam producing from these systems has a fire behaviour B2 grade according to DIN 4102.

- They are widely used in the insulation markets, the foam has a good . adhesive strength with matrix and good K-factor and dimensional stability when they react with PMDI (normal functionality) which is the recommended isocyanate for the formulation.

Sandwich Panel Systems

- They are sandwich panels in the construction of structures such as industrial buildings and cold rooms. For continuous systems, various systems with 2, 4 or 5 components are available, depending on the line characteristics.

- N-pentane is used as a blowing agent. It is used in general product types for mass production, such as continuous polyurethane systems. Our polyurethane formulas are specially tailored to customer needs.

Pipe in Pipe Systems

- ISP DP 40 series blended polyols are a pour-in-place polyurethane pipe-in-pipe rigid foam system designed n-Pentane as blowing agent. Mainly used in pipe insulation such as oil pipeline, water pipeline and heating pipeline.

Steel Products

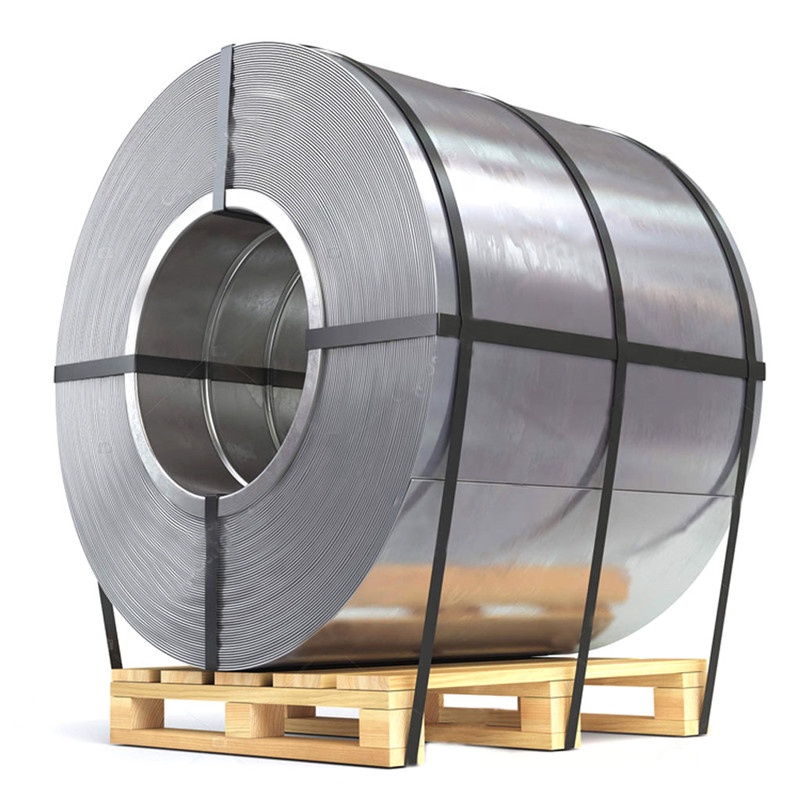

PPGI/PPGL Perpainted Galvanized/Galvalume Steel

- Thickness ( 0.2-1.5mm )

- Width ( 600-1500mm )

- Coating Mass ( 40-275g/m2 )

- Certificate ( ISO 9001 )

- Surface Treatment ( Top 15-40μm )

- Surface Treatment ( Back 5-20μm )

1060 Aluminum Coil

- Thickness ( 0.2-1.5mm )

- Width ( 600-1250mm )

- Coating Mass ( 4-38 Um )

- Certificate ( ISO 9001 )

- Surface Treatment ( PVDF/ PE/ )

- Surface Treatment ( EOXY/ PU )

Roof Tile Roll Forming Machine

GI Hot Dipped Galvanized Steel

- Thickness ( 0.2-1.5mm )

- Width ( 600-1250mm )

- Coating Mass ( 40-275g/m2 )

- Certificate ( ISO 9001 )

- Surface Treatment ( Galvanized Coated )

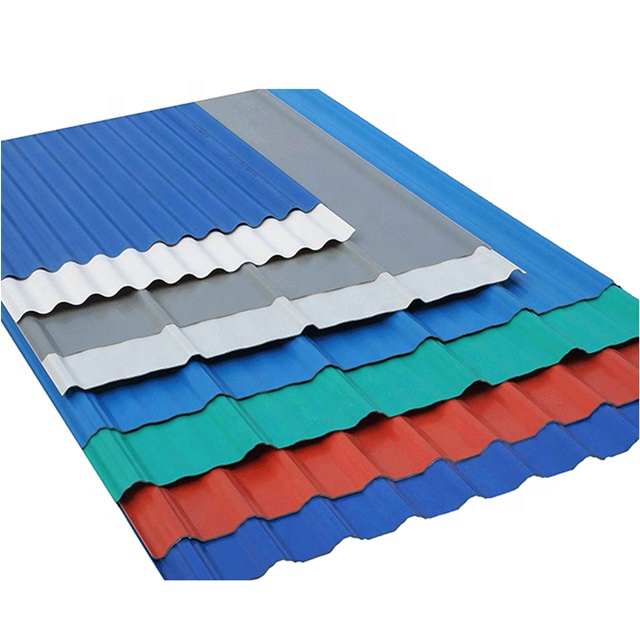

Corrugated Roofing Sheet

- Thickness ( 0.12-2.0mm )

- Width ( 600-1250mm )

- Coating Mass ( 40-275g/m2 )

- Certificate ( ISO 9001 )

- Surface Treatment ( Alu-zinc Coated)

Lu Jiang™ Color Steel

- Thickness ( 0.12-2.0mm )

- Width ( 600-1250mm )

- Coating Mass ( 40-275g/m2 )

- Certificate ( ISO 9001 )

- Surface Treatment ( PVDF/ PE/ EOXY/ PU )

GL Zinc Aluminium Hop Dipped Galvalume Steel

- Thickness ( 0.12-2.0mm )

- Width ( 600-1250mm )

- Coating Mass ( AZ30-AZ180 )

- Certificate ( ISO 9001 )

- Surface Treatment ( Alu-zinc Coated )

PCM/VCM Steel Sheet for Home Appliance

- Thickness ( 0.12-2.0mm )

- Width ( 600-1500mm )

- Coating Mass ( Top 15-40μm Back 5-20μm )

- Certificate ( ISO 9001 )

- Surface Treatment ( PVDF/ PE/ EOXY/ PU )

PrePainted Galnavized Steel

- Galvanized Steel Coil is a material produced by continuous hot-dip galvanizing process with hot-rolled steel strip or cold-rolled steel strip as the substrate .

- Hot dip galvanized coil supplied in coil form after coiling. Therefore, galvanized sheet coil can be divided into hot-rolled galvanized sheet coil and cold-rolled hot-dip galvanized sheet coil.

- They are mainly used in the fields of construction, household appliances, automobiles, containers, transportation and household industry.